- Mumbai, Bangalore, Delhi, Ahmedabad, Dubai

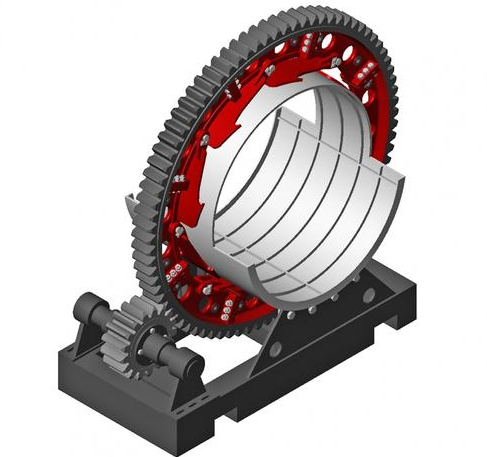

Conveyor Roller Manufacturer in Bangalore

Bangalore is one of the most important industrial cities and being in the southern part of India it is considered as a mega manufacturing capital of the country where SPECIALER as a Conveyor Roller manufacturer based in Bangalore makes its mark. Through decades of the optimal focus on the production and an excellent reputation of the company SPECIALER has established its position in the industry. We have our plant at Bangalore with an automated manufacturing facility supported by a team of highly experienced and skilled personnel to manufacture the conveyor rollers that are prescribed by the international quality standards.

Conveyor Roller Supplier In Bangalore

Being a Conveyor Roller Supplier in Bangalore SPECIALER boasts of its ability to provide endless types of conveyor rollers that are used in different industries. Despite this, we know that every business is different and they have their own specific needs and that is why we try to develop the necessary solutions. The supply chain management as a process is well-developed and we are able to deliver the products constantly and on time. From one roller to large quantities, SPECIALER offers large options as the company is able to supply the demand in an effortless manner.

Price of Conveyor Roller in Bangalore

Cost variation of conveyor rollers can be influenced in a number of ways, here are the key elements that influence the pricing:

- Material Quality: The cost of conveyor rollers depends on the type of material used in the making of the rollers. Tough and highly resistant materials such as stainless steel or specialized alloys will of course be more costly but they present better features.

- Roller Dimensions: The greatest determinant of the price of rollers is their size and dimension such as the length of the rollers, diameter, and the thickness too.

- Customization Requirements: Rollers designed for use in specific industries may attract a higher price because of design and manufacturing differences.

- Quantity Ordered: Some of the items that are ordered in large quantities have lower prices due to the bulk pricing system. At the same time, the smaller orders of the component may not entail such advantages.

- Surface Treatment: Further surfacing of the roller’s surface by coating or painting it in a way that will make it more resistant to corrosion or wear will add to the cost.

Why is SPECIALER the best brand for your Conveyor Rollers?

Trusted Expertise

SPECIALER has been involved in the manufacturing of conveyor rollers for years and it has made it a common brand in Bangalore.

High-Quality Standards

In order to meet international quality standards and guarantee the durability of our rollers, we fabricate our conveyor rollers.

Comprehensive Support

Starting from the consultation before the purchase of the products up to the provision of services after the sale, SPECIALER provides optimum support to its customers.

Competitive Pricing

We sell our conveyor rollers at cheap cost and yet supplied with high quality to enhance the value of the product.

Features of Conveyor Rollers in Bangalore

Low Maintenance

The designs of these rollers are such that they can be used for minimal maintenance, thus cutting the operational costs as well as the time that industries using them will spend on maintenance.

Versatility

Ideal for many industries such as mining, packaging, food processing industries and many others.

Smooth Operation

Dedicated design to improve engine Finesse, reduce noise during operation hence improving efficiency.

Corrosion Resistance

Less prone to corrosion hence suitable for using in areas where the material is exposed to moisture and chemicals.